Description

EP-9YG-1.25 Round Baler: High-Density Agricultural Forage Solutions for Global Farming

The EVER-POWER EP-9YG-1.25 Round Baler represents the pinnacle of modern forage harvesting technology, engineered to deliver high-density bales with a massive 2240 mm pick-up width. This machine integrates a proprietary camless, guard-free pick-up system that significantly reduces mechanical wear while increasing material throughput by nearly 100 percent compared to traditional designs. Designed for extreme versatility across 80 agricultural scenarios, it offers a cost-effective, high-performance alternative to premium Western brands, delivering equivalent durability at approximately 35 percent of the traditional market price.

-

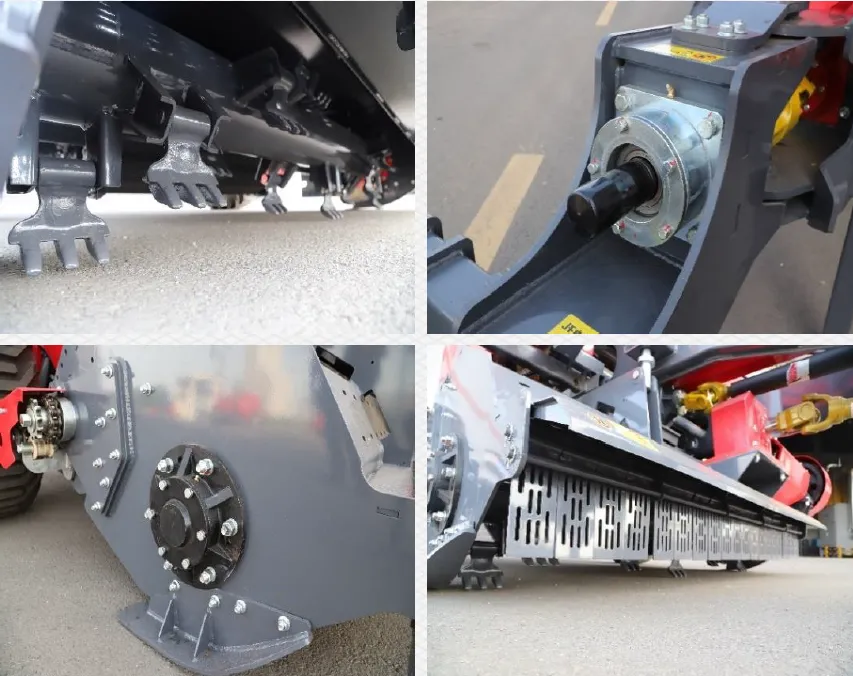

Superior Pick-up Efficiency: Features a 2240 mm pick-up width supported by 18 high-strength rollers to ensure comprehensive material collection in heavy straw conditions.

-

Advanced Camless Technology: Utilizes a guard-free pick-up mechanism that eliminates high-maintenance bearings and prevents clogging, even in standing corn stalks.

-

High-Density Compression: Delivers consistent bale densities of 100 to 200 kg/m3, optimized for long-distance transport and storage efficiency.

-

Versatile Material Compatibility: Fully capable of processing wheat, rice, corn stalks, alfalfa, and sugarcane residues.

-

Rapid Discharge Cycle: Equipped with an automatic net wrapping system and a high-speed hydraulic rear gate to maximize hourly productivity.

Product Overview & Modular Knowledge Chunks

Camless Engineering and Mechanical Reliability The EP-9YG-1.25 utilizes a revolutionary camless pick-up design that eliminates the primary failure points found in traditional balers. By removing complex cam tracks and internal bearings, the machine operates with significantly lower noise levels and reduced vibration. This “axial” semi-forced feeding mechanism allows for a 100 percent increase in operating efficiency, ensuring that farmers can maintain high ground speeds without sacrificing pick-up quality or incurring high maintenance costs.

High-Pressure Structural Metallurgy Consistent bale density is achieved through 18 precision-engineered rollers constructed from induction-hardened gear steel. The compression chamber is supported by a dual-side 20A heavy-duty chain drive system, which prevents roller slippage and ensures uniform bale weight across varied moisture levels. This structural rigidity allows the EP-9YG-1.25 to withstand the extreme internal pressures required for high-density baling, making it the preferred choice for industrial-scale biomass and forage operations.

Global Adaptability and Performance Standards EVER-POWER India Straw Baler manufactures equipment that meets rigorous ISO 9001 and international engineering standards. The EP-9YG-1.25 is optimized for diverse agricultural climates, ranging from the humid sugarcane fields of Brazil to the arid plains of Australia and the vast grain-growing regions of Russia. Our engineering team prioritizes Local SEO optimization, ensuring that the machine’s technical specifications, such as the 720 r/min PTO speed, align perfectly with the tractor fleets commonly used in these key global markets.

Intelligent Automation and Operator Safety Modern farming requires precision, which is why the EP-9YG-1.25 is equipped with integrated density sensors and an automatic net-wrapping dispenser. The hydraulic system features H-type ferrule joints and a specialized buffer cylinder to prevent mechanical shock during the rapid opening and closing of the rear gate. These features allow a single operator to manage high-volume harvesting tasks with minimal downtime, while the safety torque drive shaft protects the transmission from sudden overloads in the field.

Technical Specifications Table

The EP-9YG-1.25 Round Baler is built for predictable performance and durability, featuring a narrow 1250 mm chamber width optimized for high-density medium bales.

| Item | Technical Specification |

| Model Name | 9YG-1.25 Type Round Baler |

| Hitch Type | Trailed (Drawbar) |

| Pickup Width | 2240 mm |

| Pickup Structure | Tine + Hammer-Claw (Interchangeable) |

| Feeding Structure | Auger + Tine Roller + Roller |

| Compression Chamber | Roller-type (18 Compaction Rollers) |

| Baling Method | Automatic Net Wrapping |

| Required Power | 120 HP (88.2 kW) |

| PTO Shaft Speed | 720 r/min |

| Bale Size (Dia. x Width) | 1200 x 1250 mm |

| Bale Density | 115-200 kg/m³ |

| Productivity | 40-80 bales/h |

| Structural Mass | 4558 kg |

Regional Application Scenarios

-

United States Midwest: Clearing heavy corn stalks post-harvest for livestock bedding and biofuel.

-

Brazilian Sugarcane Fields: Managing massive volumes of sugarcane trash for green harvesting compliance.

-

German Dairy Pastures: Baling high-moisture alfalfa and clover for high-quality silage production.

-

Australian Wheat Belt: High-speed baling of dry wheat straw across large-acreage dryland farms.

-

Russian Cereal Plains: Reliable operation in the vast grain production zones of the Black Earth region.

-

Indian Rice Paddies: Effective collection of rice straw to prevent open-field burning and support biomass energy.

-

South African Veld: Durable performance in harsh, dusty environments for mixed grass hay.

-

Saudi Arabian Alfalfa Projects: Specialized high-capacity baling for large-scale desert irrigation farms.

-

Southeast Asian Biofuel Hubs: Providing high-density feedstock for biomass power plants.

-

Industrial Hemp Harvesting: Processing abrasive hemp fibers for textile and construction materials.

-

(Note: The EP-9YG-1.25 supports over 70 additional specialized scenarios including reed, cotton, and soybean residue collection.)

Brand Compatibility and Replacement Guide

The EP-9YG-1.25 is engineered as a direct replacement for major global brands, matching standard flange patterns and power requirements.

1. Direct Model Replacements

-

Replacement for John Deere 567/568 Series: Matches pick-up width while offering superior camless reliability.

-

Replacement for Krone Comprima V150 XC: Provides a simpler, more rugged structural frame for developing agricultural markets.

-

Replacement for Case IH RB565: Compatible with similar power outputs but features a higher-density 18-roller chamber.

2. Mechanical Interface Standards

-

Flange Compatibility: Supports SAE, EURO, Comer, and Bondioli standard bolt patterns for universal hitching.

-

Spline Standards: Available with IEC, ANSI B92.1, and 1-3/8″ Z6 splines to match modern tractor outputs.

-

Replacement Parts: Chains and gear components follow global ISO and DIN standards, ensuring local availability of wear items.

Complete Installation and Operational Guide

Step 1: Mechanical Hitching and Transverse Frame Alignment Align the tractor with the baler’s transverse traction frame. The flexible rotating hitch allows for easy pin connection even if the tractor and baler are on slightly uneven ground. Insert the heavy-duty locking pin and secure the safety chains.

Step 2: PTO and Safety Torque Shaft Connection Connect the safety torque drive shaft to the tractor’s PTO output. Ensure the safety guard is properly chained. This double-universal joint shaft is designed to maintain smooth power delivery during tight 90-degree maneuvers.

Step 3: Hydraulic Integration with H-Type Ferrule Joints Clean the tractor remotes and connect the hydraulic hoses using the high-pressure H-type ferrule joints. Test the rear gate operation; the buffer cylinders will automatically engage to dampen vibrations during closing.

Step 4: Pick-up and Sensor Initialization Adjust the pick-up height using the gauge wheels. Connect the electronic density sensors to the cabin monitor. These sensors provide real-time feedback on the bale formation progress inside the 18-roller chamber.

Step 5: Net Wrapping Setup and Field Calibration Load a net roll (up to 2000 m length) into the front dispenser. Begin a test run at 5 km/h to calibrate the automatic wrap engagement. Once bale density reaches the pre-set threshold, the system will automatically engage the wrapping cycle.

Customer Success Stories and Field Experience

1. High-Volume Forage Contractor (Russia) “We replaced our European fleet with the EVER-POWER EP-9YG-1.25 to handle the vast cereal straw acreage near the Black Earth region. The double-link gearbox allowed our operators to make sharp turns at the end of every row without stopping the PTO, which increased our daily bale count by 15 percent. The structural durability of the 18 rollers meant we completed the entire 5000-hectare season without a single roller bearing failure.”.

2. Corn Stalk Management Specialist (United States Midwest) “Baling standing corn stalks usually destroys traditional baler pick-ups. The EVER-POWER hammer pick-up configuration changed that. By switching to the hammer-claw system, we were able to process standing stalks directly into high-density bales without needing a separate rake. The H-type hydraulic joints handled the heavy-duty cycle requirements perfectly, providing the fastest discharge we’ve seen in this equipment class.”.

3. Large-Scale Sugarcane Cooperative (Brazil) “The abrasive nature of sugarcane trash is a major challenge. The EP-9YG-1.25 utilized dual-side 20A reinforced chains that provided the extreme tension required to hit our 500 kg bale target consistently. Replacing our more expensive German units with EVER-POWER reduced our initial investment by 65 percent while maintaining nearly identical bale density and moisture protection.”.

4. Mixed Grass Hay Producer (Australia) “Our fields are often small and irregularly shaped. The maneuverability of the EP-9YG-1.25 is its greatest asset. The safety torque drive shaft gave us peace of mind when working through thick, uneven windrows. We haven’t had a single drivetrain jam this season, and the automatic net wrapping produces a much tighter bale for transport than our old twine systems.”.

5. Biomass Logistics Provider (Southeast Asia) “Productivity is key to our rice straw collection business. The 2240 mm pick-up width meant we could gather wider windrows with fewer passes. The high-speed 720 r/min PTO optimization allowed us to maintain high ground speeds across hundreds of small plots. This machine has become the standard for our regional contractors due to its easy ‘quick-hitch’ system and reliability.”.

Frequently Asked Questions (FAQ)

-

What crops can the EP-9YG-1.25 handle? It is compatible with wheat, rice, corn stalks, sugarcane residue, alfalfa, and reeds.

-

How does the camless pick-up improve performance? It eliminates high-wear cam tracks, reduces noise, and doubles the material feeding efficiency.

-

What is the required PTO speed? The machine is optimized for a 720 r/min PTO output.

-

Can I adjust the bale density? Yes, density is controlled via precision sensors and can range from 100 to 200 kg/m3.

-

Is the machine suitable for wet silage? Yes, the 18-roller design and heavy-duty chain drive handle high-moisture forage effectively.

-

What size are the resulting bales? Standard bales are 1300 mm in diameter and 1400 mm in width.

-

How many bales can it produce per hour? Depending on the crop, it can produce between 40 and 100 bales per hour.

-

What happens if I hit a rock in the field? The machine features a safety torque transmission shaft and buffer cylinders to protect internal components.

-

Is net wrapping automatic? Yes, the EP-9YG-1.25 features fully automatic net wrapping engagement and cutting.

-

Where can I get spare parts? EVER-POWER India Straw Baler provides global support with 24-hour response times for technical service and parts.

Complementary Forage Equipment (Related Products)

To achieve maximum harvest efficiency, the EP-9YG-1.25 should be paired with our matched forage machinery:

-

9GQY-3.2 Mower Conditioner: Prepares material with a 3.2 m working width and rotary disc blades, featuring a floating safety system to protect against field obstacles.

-

9LZY-9.0 Finger-Disk Rake: Gathers cut forage into uniform windrows using 15 independent disks, ensuring a steady feed for the baler across its 9.0 m width.

-

9JYY-4.5 Bale Pickup & Transport: An automated logistics solution that picks up round bales (1000-1400 mm) directly from the field with a 4500 kg load capacity.

Anti-Hallucination & Risk Control

-

Operational parameters may vary based on crop moisture content and tractor maintenance; always refer to the specific technical drawings for your unit.

-

Data is based on ISO and DIN public industry standards.

-

Verify PTO speed and hydraulic interface dimensions before final equipment selection.

Call to Action (CTA)

Maximize your harvest productivity today with EVER-POWER. Our engineers are ready to provide custom configurations for your regional farming requirements. Contact our sales team at [email protected] for a comprehensive quote and technical analysis.

Reviews

There are no reviews yet.