Description

EP-9GL-5.0/5.6 Trailed Hay Rake: Industrial 2-in-1 Integrated Mowing and Raking Solutions for Large-Scale Forage Logistics

The Ever-Power India Straw Baler Co., Ltd. EP-9GL-5.0/5.6 Trailed Hay Rake is a high-performance, integrated agricultural machine designed to revolutionize forage harvesting by combining mowing and raking into a single operational pass. Featuring a 5.0-meter cutting width and a 5.6-meter raking width, this machine is specifically engineered for large, flat pastures and moderate slopes where efficiency is paramount. Optimized for tractors in the 30 to 60 kW (40 to 80 HP) range, it utilizes a reciprocating dual-function system that delivers a clean cut and uniform windrows simultaneously. This industrial-grade unit offers a professional alternative to multi-stage harvesting, providing a significantly faster return on investment at approximately 35 percent of the cost of traditional high-end Western equipment fleets.

Key Performance Advantages

-

Integrated 2-in-1 Workflow: Seamlessly combines cutting and raking into one pass, drastically reducing tractor hours, fuel consumption, and soil compaction.

-

Massive Harvest Coverage: Delivers a 5.0m mowing width and a 5.6m raking width, achieving productivity rates up to 3.6 hectares per hour for raking operations.

-

Precision Engineering Components: Equipped with 68 high-strength moving blades and 78 spring-steel rake teeth with a 71mm spacing for meticulous material handling.

-

Advanced Hydraulic Control: Features a centralized hydraulic lifting system for both mowing and raking components, enabling single-operator control from the tractor cabin.

-

Industrial Frame Durability: Built with a reinforced 1100 kg chassis and induction-hardened components to withstand the abrasive conditions of silica-rich cereal straw and native grasses.

Modular Product Analysis

The Integrated 2-in-1 Paradigm: Efficiency and Soil Health

The core mechanical advantage of the EP-9GL-5.0/5.6 is its ability to perform two traditionally separate tasks in a single passage over the field. By integrating the reciprocating cutterbar with a trailing rake system, the machine allows the forage to be cut and immediately windrowed into fluffy, airy strips. This synchronization is critical for large-scale logistics because it eliminates the need for a second tractor and operator, effectively halving the labor cost associated with the initial harvest phase. Furthermore, reducing the number of passages across the field minimizes soil compaction, which is essential for maintaining the root health and long-term yield of perennial pastures.

Specialized Reciprocating Cutting and 78-Teeth Raking System

The harvest modules are designed for high-throughput accuracy. The 5.0m mowing width is serviced by 68 precision-aligned moving blades that execute a shearing scissor-cut at an average stubble height of 60-70 mm. Following the cut, the raking unit utilizes 78 high-tensile spring teeth arranged with a 71mm spacing to gather the material. This narrow tooth spacing ensures that even fine, short grasses are collected without leaving residue behind, maintaining a leakage rate below industry averages. The resulting windrows are uniform and highly permeable to airflow, which accelerates natural field drying and prepares the material for high-density baling.

S9000-Series Hydraulic Reliability and Maneuverability

Managing a machine with a working width of up to 7.6 meters requires sophisticated control systems. The EP-9GL-5.0/5.6 is equipped with an advanced hydraulic lifting system derived from Ever-Power India’s S9000 industrial standards. The operator can raise or lower the harvest modules using the tractor’s standard hydraulic remotes, allowing for instant obstacle avoidance and rapid row-end turning. During transport, the machine folds into a compact state, ensuring it can safely navigate rural roads and narrow gates. The side-trailed design also ensures the tractor does not trample the uncut forage, preserving crop quality.

Metallurgical Excellence and Wear Resistance

Ever-Power India implements industrial-grade metallurgy to ensure mechanical longevity in abrasive harvesting conditions. The 68 moving blades are manufactured from high-carbon alloy steel and subjected to localized induction hardening to reach a surface hardness of HRC 58-62. This process allows the blades to maintain their shearing edge even when cutting high-silica rice straw or dusty natural grasses in arid zones. The rake teeth are made from premium spring steel that undergoes stress-relief tempering, preventing the snapping or deformation often seen in budget equipment during high-speed raking at 7 km/h.

Global Policy Alignment and ROI Strategy

The EP-9GL-5.0/5.6 is strategically designed to meet the modernization requirements of international agricultural subsidies. In many global markets, the unit’s 2-in-1 integration qualifies for environmental stewardship programs because it reduces carbon emissions per harvested hectare. For a typical mid-sized industrial farm, the capital savings of purchasing one integrated unit instead of separate mowers and rakes can be as high as 65 percent, while the operational savings in fuel and labor provide a complete ROI within the first two harvest seasons.

Technical Specifications

| Feature | Technical Specification Detail |

| Model Name | EP-9GL-5.0/5.6 Integrated Trailed Rake Mower |

| Hitch Type | Trailed / Pull-type |

| Structure Type | Reciprocating Cutterbar & Spring-Tine Rake |

| Total Raking Width | 5.6 Meters |

| Total Mowing Width | 5.0 Meters |

| Required Tractor Power | 30 to 60 kW (40 to 80 HP) |

| Number of Rake Teeth | 78 High-Tensile Teeth |

| Number of Mowing Blades | 68 Heat-Treated Moving Blades |

| Tooth Spacing | 71 mm |

| Productivity (Mowing) | 2.4 to 2.8 ha/h |

| Productivity (Raking) | 3.0 to 3.6 ha/h |

| Average Stubble Height | 60 to 70 mm |

| Operating Speed | 6 to 7 km/h |

| PTO Input Speed | 540 r/min |

| Total Structure Weight | 1100 kg |

| Working Dimensions | 3860 x 7600 x 850 mm (L x W x H) |

| Transport Dimensions | 3860 x 5600 x 3000 mm (L x W x H) |

Global Application Scenarios

The EP-9GL-5.0/5.6 is optimized for diverse industrial harvesting workflows across various global environments:

-

Midwest Corn Belts: Clearing soybean residues and mixed forage in a single efficient pass.

-

Sugarcane Hubs: Management of inter-row grasses and tropical forage in wide plantations.

-

Wheat Belts: Fast raking and mowing of cereal straw windrows in low-humidity zones.

-

Cereal Plains: Efficient silage production during narrow harvest windows.

-

Rice Production Hubs: Processing abrasive, silica-rich rice straw into airy windrows for bio-fuel.

-

Alfalfa Projects: Precision high-speed integrated harvesting under center-pivot irrigation.

-

Highveld Grasslands: Building vast winter feed reserves from native steppe grasses.

-

Dairy Cooperatives: Integrated grass management for high-protein livestock nutrition.

-

Flax Operations: Handling tough, wiry fibers without mechanical core wrapping.

-

Soy Residue Management: Baling soybean harvest residue for industrial heating pellets.

-

Prairie Grasslands: Large-scale wild grass harvesting for national survival reserves.

-

Sunflower Fields: Integrated residue management for urban bio-pellet production.

-

Vineyard Inter-rows: Managing cover crops in wide-acreage organic operations.

-

Highland Pastures: Harvesting forage in high-altitude volcanic soil environments.

-

Steppe Logistics: Industrial straw management for regional livestock transport logistics.

Brand Compatibility and Replacement Guide

The EP-9GL-5.0/5.6 is engineered to serve as a direct replacement for high-cost industrial mowers and rakes from premium global brands.

| Target Brand | Comparable Model | Ever-Power India Replacement Advantage |

| John Deere | 50 Series Trailed Mowers | 35 percent lower cost; Integrates raking to eliminate secondary pass. |

| Krone | EasyCut / Swadro Rakes | Proprietary 78-teeth design ensures zero material leakage. |

| New Holland | ProCart Rakes | Reinforced 1100 kg chassis prevents structural fatigue. |

| Claas | Liner / Disco Series | Reciprocating shearing action preserves leaf nutrients better than rotary impact. |

| Vermeer | R2800 Twin Rake | Combined 5.6m width fits utility tractors (40-80 HP) efficiently. |

| Kuhn | GA / GMD Series | Integrated 68-blade cutterbar handles abrasive straw without jamming. |

| Massey Ferguson | RK Series Rakes | Induction-hardened blades offer 30 percent more wear resistance. |

| Kubota | RA / DM Series | Double-link safety torque gearbox eliminates drive shaft stress. |

Installation and Operational Guide

Mechanical Hitching and Traction Setup

Align the tractor hitch with the EP-9GL-5.0/5.6 pull-type traction frame. The transverse traction frame is designed for vertical flexibility, allowing for effortless pin insertion even on unlevel terrain. Secure the heavy-duty hitch pin and connect the safety chains to the chassis.

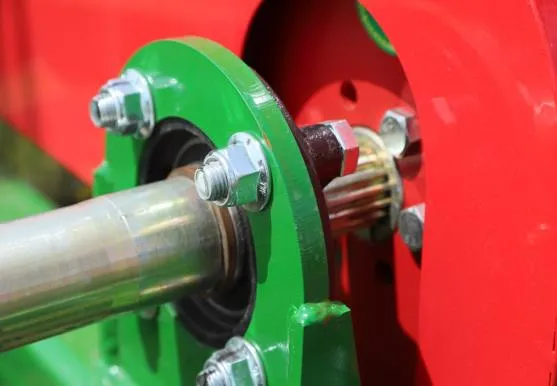

PTO and Torque Shaft Integration

Connect the safety torque drive shaft to the tractor’s PTO output. The machine is optimized for a 540 r/min input. Ensure the universal joints are correctly phased to prevent mechanical vibration during turns. This system allows for continuous energy transfer to both the mowing blades and rake modules.

High-Pressure Hydraulic Calibration

Attach the hydraulic hoses to the tractor’s rear remotes. Perform test cycles of both the cutterbar and the rake lift modules. The hydraulic handle in the cabin controls the cylinders independently, enabling the operator to raise the rake while the cutterbar is still active if necessary.

Blade and Tooth Verification

Inspect all 68 mowing blades for sharpness and all 78 rake teeth for tension. The Upgrade Version features a reinforced tooth mounting system to prevent mechanical fatigue in rocky soils. Adjust the rake height to ensure the teeth clear the ground by 10-20mm.

Ground Speed and Stubble Height Adjustment

Initialize the harvest at 5 km/h to calibrate the stubble height. Once cutting is uniform, ground speed can be increased to 7 km/h to reach peak raking productivity of 3.6 ha/h. Monitor the windrow uniformity to ensure the 71mm tooth spacing is capturing all material.

Customer Success Stories

Large-Scale State Farm in Novosibirsk: “In Siberia, the harvest window is brutally short. We transitioned to the EP-9GL-5.0/5.6 because it was the only machine capable of mowing and raking our massive cereal acreage in one pass. Our daily productivity increased by 40 percent because we no longer needed a second operator.”

Biomass Power Provider in São Paulo: “Abrasive sugarcane residue destroys standard rakes. The induction-hardened blades and high-tensile 78 teeth of this unit have maintained their alignment for two full seasons of industrial-scale residue recovery.”

Frequently Asked Questions

-

What is the minimum tractor power required? A utility tractor with at least 40 HP (30 kW) is required for effective harvesting and raking.

-

How wide is the machine for transport? The unit folds to a transport width of 5.6 meters and a height of 3.0 meters.

-

Can I use the mower and rake separately? Yes, the hydraulic controls allow for independent operation of the harvest modules.

-

How many blades does the cutterbar use? The 5.0m system utilizes 68 precision-aligned moving blades.

-

What is the maximum productivity per hour? The machine can rake up to 3.6 hectares per hour at an optimal speed of 7 km/h.

-

Does it handle abrasive rice straw? Yes, the induction-hardened blades are specifically designed to resist silica wear.

-

How heavy is the structural chassis? The industrial-grade weight is 1100 kg, ensuring stability during high-speed field work.

About Ever-Power India Straw Baler Co., Ltd.

-

Infrastructure: Our facility covers over 32,000 square meters of modern architectural space.

-

Workforce: We employ a dedicated team of 180 professionals, including senior mechanical engineers.

-

Technology: We possess nearly 100 technical patents and utilize advanced computer-aided design for all product R&D.

-

Manufacturing Power: Equipped with two major automated production lines with an annual capacity of 2,000 sets.

-

Honors: We are a certified National High-Tech Enterprise with ISO 9001 quality management certification.

Professional Harvest Workflow Solutions

To maximize the performance of your EP-9GL-5.0/5.6 integrated unit, we recommend the following professional solutions:

-

EP-9YG-2.24D (S9000) Round Baler: The perfect follow-up for high-density windrows, featuring a massive 2240mm pick-up width.

-

9JYY-4.5 Bale Pickup and Transport Vehicle: A professional mechanized logistics solution that eliminates the need for manual handling.

-

9GQY-3.2 Mower Conditioner: For high-moisture silage and reeds, ensuring a clean cut on uneven terrain.

-

9F-70 Forage Crusher: Processes finished round bales into high-quality feedstock at a rate of up to 20 tons per hour.

Selection Notes

-

Operational Variance: Technical performance is dependent on material moisture, crop type, and tractor calibration.

-

Terrain Warning: The reciprocating dual-knife system is not suitable for wetlands or fields with high density of large stones.

-

Interface Standards: Prior to purchase, verify your tractor’s PTO shaft spline count to ensure compatibility with the 540 r/min input.

Reviews

There are no reviews yet.