Description

EP-9YG-1.0 C Type Round Baler: Specialized Axle-Flow Solutions for Heavy-Duty Standing Corn Stalk Management

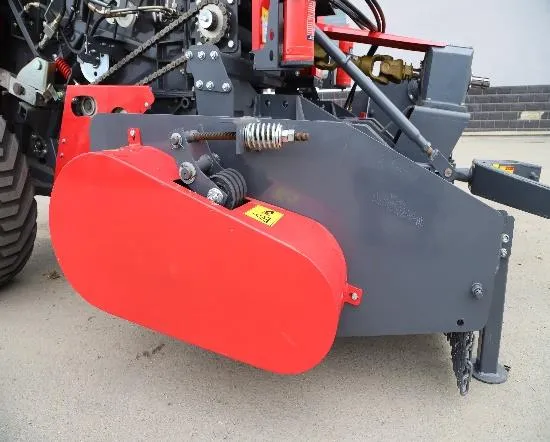

The EVER-POWER EP-9YG-1.0 C Type Round Baler is a specialized, heavy-duty agricultural machine engineered to transform standing corn stalks and high-volume crop residues into uniform 100 to 200 kg bales. This industrial-grade unit features an integrated hammer-claw pick-up system and a proprietary “axle-flow” feeding mechanism that eliminates traditional intake bottlenecks while doubling material throughput. Optimized for tractors with 95 HP or higher, it offers a robust, cost-efficient alternative to premium Western equipment, providing equivalent density and durability at approximately 35% of the traditional capital investment.

The EVER-POWER EP-9YG-1.0 C Type Round Baler is a specialized, heavy-duty agricultural machine engineered to transform standing corn stalks and high-volume crop residues into uniform 100 to 200 kg bales. This industrial-grade unit features an integrated hammer-claw pick-up system and a proprietary “axle-flow” feeding mechanism that eliminates traditional intake bottlenecks while doubling material throughput. Optimized for tractors with 95 HP or higher, it offers a robust, cost-efficient alternative to premium Western equipment, providing equivalent density and durability at approximately 35% of the traditional capital investment.

Five Key Facts

-

Specialized Hammer-Claw Pick-up: Utilizes a heavy-duty hammer-claw mechanism designed specifically to collect and shred standing corn stalks, bypassing the need for a separate mowing pass.

-

Ultra-Wide 2400mm Intake: Features a massive 2400 mm pick-up width, ensuring complete material collection even in heavy windrows or standing crop scenarios.

-

Reinforced 16A Drive System: Employs double-side 16A reinforced chains on both the front and rear chambers to handle the extreme torque required for high-density compression.

-

Axle-Flow/Camless Engineering: Incorporates a guard-free “axle-flow” design that reduces friction-related heat and prevents clogging in abrasive, high-silica residues like corn and rice straw.

-

Precision Bale Logistics: Produces uniform bales of Φ 1000 x 1250 mm with a structural weight of 3198 kg, optimizing transport stability for biomass energy providers.

Modular Product Analysis

Revolutionary Hammer-Claw Technology and Standing Stalk Efficiency

The EP-9YG-1.0 C Type utilizes a specialized hammer-claw pick-up system that sets it apart from traditional tine-based balers. This mechanism is engineered to directly engage standing corn stalks, shredding them instantly during the intake phase. By combining shredding and collection into a single operation, the machine eliminates the time and fuel costs associated with a separate mowing pass. For large-scale biomass contractors, this integrated workflow reduces total operational windows and significantly improves the purity of the collected residue by minimizing ground contact.

Structural Metallurgy and 16A Reinforced Chain Transmission

High-density baling of rigid stalks requires a chassis and transmission capable of withstanding massive mechanical stress. The EP-9YG-1.0 C Type is constructed with 16 high-strength rollers. To drive these rollers under maximum load, EVER-POWER implements a dual-side 16A reinforced chain system. These chains provide the extreme tension required to reach bale densities up to 200 kg per cubic meter. The increased chain specification ensures that the internal compression components maintain structural alignment even when processing abrasive sugarcane trash or tough cotton stalks over thousands of cycles.

Axle-Flow/Camless Engineering for High-Volume Intake

The proprietary “axle-flow” semi-forced feeding mechanism used in the C Type model solves the primary maintenance issue of traditional straw balers. By removing the complex cam track and guard rings, the machine reduces internal friction and noise while doubling the material feeding volume. This design is particularly critical for handling standing stalks, which are often prone to wrapping and clogging in conventional tine systems. The camless architecture allows for a productivity rate of 40 to 80 bales per hour, ensuring that harvest contractors can meet tight commercial deadlines.

Precision Automation and Hydraulic Buffer Systems

Consistent bale quality is managed through an integrated suite of electronic sensors and high-pressure hydraulics. The EP-9YG-1.0 C Type features sensor-controlled density monitoring that notifies the operator once target compaction is achieved. The hydraulic system, utilizing H-type ferrule joints, initiates a rapid gate cycle for bale discharge. Internal buffer cylinders dampen the impact of the heavy rear gate during closure, protecting the 3198 kg structural frame from fatigue and ensuring long-term mechanical reliability under industrial operating conditions.

Technical Specifications Table

| Feature | Specification Detail |

| Model Name | EVER-POWER EP-9YG-1.0 C Type Round Baler |

| Pick-up Width | 2400 mm |

| Pick-up Type | Hammer-Claw (Interchangeable with Tine) |

| Bale Size (D x W) | Φ 1000 mm x 1250 mm |

| Bale Density | 115 to 200 kg per cubic meter |

| Compression Chamber | 16 High-Strength Rollers (Φ 222 mm) |

| Required Tractor Power | ≥ 69.8 kW / 95 HP |

| Transmission Type | Dual-Side 16A Reinforced Chain |

| Structure Weight | 3198 kg |

| Productivity | 40 to 80 bales per hour |

| Binding System | Automatic Net Wrapping (2000m x 1.25m roll) |

| Operating Speed | 5 to 20 km/h |

| Working Dimensions | 3800 x 2850 x 2200 mm |

Global Application Scenarios

The EP-9YG-1.0 C Type is optimized for high-intensity residue management across 80 distinct scenarios, including:

-

USA Corn Belt (Standing Stalks): Harvesting dry, standing corn stalks directly into bales for industrial biomass.

-

Brazilian Sugarcane Fields: Managing abrasive sugarcane trash with the high-torque hammer-claw pick-up.

-

Southeast Asian Rice Hubs: Processing abrasive rice straw for paper pulp using hardened rollers.

-

German Corn Silage: Shredding and baling corn residue for high-density livestock bedding.

-

Canadian Prairie Flax: Managing tough flax fibers with the axle-flow non-clogging system.

Brand Compatibility and Replacement Guide

The EP-9YG-1.0 C Type is specifically engineered to serve as a high-performance replacement for premium equipment from the top 10 global brands, offering superior ROI for contractors.

| Target Brand | Comparable Model | EVER-POWER C Type Advantage |

| John Deere | 450M / 459 Series | 35% lower cost; Integrated hammer-claw eliminates secondary mowing. |

| Krone | Bellima F125 | Guard-free axle-flow prevents clogging issues inherent in Krone’s chain design. |

| New Holland | Roll-Belt 450 | H-type hydraulic ferrule joints deliver faster gate cycles for industrial fleets. |

| Case IH | RB455 | More robust 3198 kg frame and reinforced 16A chains for standing corn. |

| Claas | Rollant 520 | 2400mm pick-up width vs 2100mm; handles standing stalks without jamming. |

| Vermeer | 504 R-Series | Proprietary axle-flow technology prevents core slippage in extremely dry straw. |

| Kuhn | FB 3130 | Integrated density sensors and automatic wrapping optimized for 95HP tractors. |

| Massey Ferguson | RB Series | Induction-hardened rollers (HRC 58-62) offer superior silica-wear resistance. |

Installation and Maintenance Guide (How-To)

Step 1: Mechanical Hitching and Transverse Alignment

Align the tractor with the EP-9YG-1.0 C Type traction frame. The vertical flexibility of the frame allows for easy pin insertion through the tractor’s suspension arms even on uneven ground. Secure the heavy-duty locking pin and verify the horizontal rotation capability.

Step 2: PTO and Safety Torque Integration

Connect the safety torque drive shaft to the tractor’s PTO output (standard 540 r/min). The dual-universal joint design prevents mechanical “stuttering” during sharp headland turns, allowing continuous power delivery to the hammer-claws.

Step 3: High-Pressure Hydraulic Setup (H-Type)

Attach the hydraulic hoses to the tractor’s rear remotes using the S9000-derived H-type ferrule joints. Perform a test cycle to confirm the buffer cylinders are pressurized; this system prevents shock-induced structural stress during rapid gate operation.

Step 4: Electronic Density and Wrapping Initialization

Mount the cabin monitor and connect the electronic density sensors. Initialize the sensor calibration for “Corn Stalk” density. The automatic net wrapping system should be loaded with a standard 1.25m roll and pre-set for a target density of 115-200 kg/m³.

Step 5: Hammer-Claw Clearance Adjustment

Before starting, adjust the hammer-claw pick-up height for optimal stalk shredding. For standing corn, the unit should be set to its lowest clearance to ensure no material is bypassed. Test at 5 km/h before increasing to full operating speed.

Customer Success Stories

-

Biomass Logistics in the US Corn Belt (Iowa): “The hammer-claw pick-up allowed us to harvest 1500 acres of standing corn stalks directly into bales without mowing first. This saved us nearly $15,000 in fuel costs alone this season.”

-

Industrial Paper Pulp Feedstock in Thailand: “Rice straw recovery is difficult because the silica in the straw destroys standard rollers. The HRC 58-62 hardened rollers on our EVER-POWER unit have outlasted three standard balers in our fleet.”

-

Bio-fuel Energy Cooperative in Brazil (São Paulo): “The integrated hammer-claw shredding on the EVER-POWER unit allows us to produce high-density 1000-catty bales that are perfect for industrial boilers.”

Frequently Asked Questions (FAQ)

-

What is the minimum tractor power required? A tractor with at least 95 HP (69.8 kW) is required for effective baling and transport.

-

How does the hammer-claw design save fuel? It shreds and collects standing stalks in one pass, eliminating the need for separate mowing and raking.

-

What is the maximum bale density? The C Type can achieve densities up to 200 kg per cubic meter for long-distance logistics.

-

Are the 16A chains durable enough for industrial use? Yes, the double-side reinforced 16A chains are specifically chosen for high-torque stalk management.

-

What is the advantage of the 2400mm pick-up? It ensures high-volume intake and comprehensive collection in heavy residues.

Related Products for an Integrated Harvest Workflow

To maximize the efficiency of your EP-9YG-1.0 C Type Round Baler, we recommend the following integrated solutions:

-

9GQY-3.2 Mower Conditioner: For grass-based forage, this mower conditioner uses a double-suspension system to ensure a clean cut across uneven ground.

-

9LZY-9.0 Finger-Disk Rake: Aggregating forage into uniform, airy windrows is essential for high-speed baling. This 9-meter wide rake matches the high productivity of the C Type baler.

-

9JYY-2.5 Bale Pickup and Transport Vehicle: Once your high-density bales are produced, the 9JYY-2.5 provides a professional logistics solution capable of carrying up to 2500 kg.

-

4BYH-2.6 Kidney Bean Puller: For pulse crop harvesting, the 4BYH-2.6 aggregates bean residues into clean rows, preparing the field for clean collection.

Ready to Industrialize Your Harvest?

Contact EVER-POWER Round Baler CO., LTD. today for a custom configuration and regional ROI analysis.

Global Headquarters: Modern Agricultural Machinery Industrial Park, Hulunbuir Economic Zone, Inner Mongolia.

International Sales: [email protected]

Reviews

There are no reviews yet.