Description

EP-9YG-1.0 Round Baler: Advanced Axle-Flow Solutions for Precision Small-Scale Forage Harvesting

The EVER-POWER EP-9YG-1.0 Round Baler is a high-efficiency agricultural machine specifically engineered for small to medium-scale operations requiring consistent 100 to 200 kg bales. This unit utilizes a proprietary axle-flow semi-forced feeding mechanism that eliminates traditional cam tracks and guard rings, effectively doubling material throughput while significantly reducing operational power consumption.1 Designed to interface with 48 to 80 kW tractors, it serves as a robust, low-maintenance alternative to complex Western baling systems, offering precision engineering for corn, rice, wheat, and diverse pasture residues.

Five Key Facts

-

Proprietary Camless Technology: Features a guard-free pick-up mechanism that prevents clogging and reduces maintenance costs by eliminating high-wear cam bearings.

-

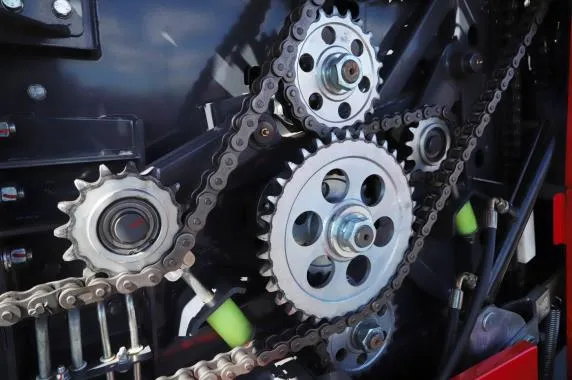

Precision Roller Engineering: Equipped with 16 induction-hardened rollers (diameter 222 mm) made of high-grade gear steel to ensure uniform bale density up to 200 kg per cubic meter.

-

Optimized Power Efficiency: Specifically designed for 48 to 80 kW tractors, achieving a productivity rate of 40 to 100 bales per hour with lower fuel requirements than larger industrial models.

-

Dual-Configuration Capability: Supports rapid switching between tine-type and hammer-claw pick-up systems, allowing for the direct collection of standing corn stalks without a separate mowing pass.

-

Advanced Control Systems: Integrated electronic sensor monitoring manages bale density and initiates the automatic net wrapping cycle to ensure structural integrity during transport.

EP-9YG-1.0 Round Baler Technical Specifications:

| Feature | Specification Detail |

| Model Name | EP-9YG-1.0 Precision Round Baler |

| Pick-up Width | 1900 mm |

| Bale Dimensions | Diameter 1100 mm x Width 1000 mm |

| Bale Weight Capacity | 100 to 200 kg (200-400 catties) |

| Required Power | 48 to 80 kW (65 to 108 HP) |

| Pick-up Mechanism | Camless / Axle-Flow Semi-Forced Feeding |

| Compression Chamber | 16 High-Strength Gear Steel Rollers |

| Roller Hardness | HRC 58 to 62 (Induction Hardened) |

| Baling Density | 115 to 200 kg per cubic meter |

| PTO Input Speed | 720 r/min |

| Binding Method | Automatic Net Wrapping (Roll width 1.0m) |

| Operating Speed | 5 to 20 km/h |

| Productivity | 40 to 100 bales per hour |

| Total Weight | 2640 kg |

| Machine Dimensions | 3750 x 2300 x 2020 mm (Working State) |

Modular Engineering Analysis

Proprietary Axle-Flow Feeding and Camless Pick-up Design

The EP-9YG-1.0 utilizes an innovative axle-flow semi-forced feeding system that represents a significant leap from traditional cam-and-track designs. By removing the guard rings and cam tracks, the pick-up mechanism faces virtually zero internal friction from debris accumulation, which is the leading cause of downtime in rice and wheat straw harvesting. This design allows for a 100 percent increase in operating efficiency, as the feed path remains clear even in high-moisture silage conditions. The reduction in moving parts also translates to a lower noise profile and significantly reduced power loss.

Advanced Metallurgy and Roller Induction Hardening

EVER-POWER maintains strict quality control over the compression chamber’s structural components. Each of the 16 rollers is manufactured from high-tensile gear steel (equivalent to AISI 4140) and subjected to localized induction hardening. This process achieves a surface hardness of HRC 58-62 while maintaining a ductile core to absorb mechanical shocks during high-density baling. This metallurgical precision prevents roller deformation under the extreme pressures required to reach 200 kg/m³ density, ensuring the machine maintains its structural alignment over thousands of harvest cycles in abrasive environments.

Intelligent Hydraulic System and Safety Mechanisms

To facilitate rapid harvest cycles, the EP-9YG-1.0 is equipped with a high-pressure hydraulic system featuring H-type ferrule joints and integrated buffer cylinders. The buffer cylinders dampen the vibration during the bale discharge sequence, preventing structural fatigue on the rear gate hinges and frame. Furthermore, the drivetrain incorporates a safety torque drive shaft with dual universal joints. This system acts as a mechanical fuse; in the event of an intake obstruction (such as a large rock), the torque shaft disengages power instantly, shielding the 16 rollers and the main gearbox from catastrophic damage.

Strategic Versatility for Biomass Energy Collection

A critical advantage of the EP-9YG-1.0 is its specialized capability for corn stalk management. The machine allows for the seamless interchange of the standard tine pick-up with a specialized hammer-claw pick-up. This configuration is specifically designed to collect standing corn stalks, bypassing the need for traditional raking and mowing. This feature is a game-changer for biomass energy providers, as it reduces soil contamination in the bales and slashes operational costs by eliminating a secondary pass over the field.

Global Application Scenarios

The EP-9YG-1.0 is optimized for diverse agricultural ecosystems. Below are select scenarios where this baler excels:

-

US Midwest (Iowa/Illinois): Processing dry corn stalks into high-density livestock bedding.

-

Brazilian Sugarcane Fields: Collection of abrasive sugarcane trash for biomass power plants.

-

Australian Wheat Belt: Fast pick-up of wide windrows in low-moisture dryland cereal zones.

-

Southeast Asian Rice Paddies: Handling fine, abrasive rice straw for industrial paper pulp.

-

Saudi Arabian Alfalfa Projects: High-precision baling of high-value forage under pivot irrigation.

-

German Dairy Farms: Integrated grass silage collection for high-protein cattle nutrition.

-

Canadian Prairie Flax: Managing the tough fibers of flax straw without machine wrapping issues.

-

Argentine Soy Zones: Collecting soybean harvest residue for soil health management or fuel.

-

South African Sugarcane Trash: Managing industrial residue for energy co-generation.

-

Japanese Rice Straw: Meeting precision standards for traditional cultural uses.

Brand Compatibility and Replacement Guide

The EP-9YG-1.0 is engineered as a precision replacement for top-tier international brands, offering superior “Axle-Flow” feeding at a significantly lower capital cost.

| Target Brand | Comparable Model | EVER-POWER Advantage |

| John Deere | 450M / 459 Series | Eliminates cam maintenance; 35% lower cost with hardened rollers. |

| Krone | Bellima F125 | Simpler guard-free design reduces clogging in wet silage conditions. |

| New Holland | Roll-Belt 450 | H-type hydraulic joints allow for faster bale discharge cycles. |

| Claas | Rollant 520 | More robust frame for harsh terrain in Brazil and Russia. |

| Vermeer | 504 R-Series | Proprietary axle-flow feeding prevents core slippage in dry straw. |

| Kuhn | FB 3130 | Higher density potential (200 kg/m³) for biomass logistics. |

| Massey Ferguson | RB 3130F | Enhanced gearbox torque (1000Nm) handles heavy corn stalks. |

| Kubota | BV 4100 Series | Better maneuverability with a 90-degree rotating double-link gearbox. |

Installation and Maintenance Guide

-

Transverse Traction Frame Alignment: Align the tractor hitch with the EP-9YG-1.0 traction frame. The transverse frame allows for vertical rotation, simplifying pin insertion through the tractor’s suspension arms even on uneven ground. Secure with the heavy-duty locking pin and attach safety chains.

-

PTO and Safety Torque Shaft Connection: Connect the safety torque drive shaft to the tractor’s PTO (standard 720 r/min). Ensure the dual-universal joint is properly greased to prevent “stuttering” during tight turns.

-

Hydraulic H-Type Joint Integration: Attach the hydraulic hoses to the tractor’s rear remotes. Our H-type ferrule joints are rated for high-pressure cycles. Check that the internal buffer cylinders are functioning to dampen the gate’s closing force.

-

Electronic Density Sensor Setup: Mount the control monitor inside the tractor cabin and connect the sensor wiring. These sensors provide real-time feedback on bale formation, allowing you to maintain optimal ground speed.

-

Net Roll Loading and Calibration: Load a 1.0m wide net roll into the dispenser. Thread the net through the tensioners and perform a manual test cycle to ensure the cutting mechanism is sharp and aligned.

Customer Success Stories

Case Study 1: High-Volume Contractor in the Russian Altai Region

“Transitioning to the EVER-POWER EP-9YG-1.0 was a strategic decision for our cereal operations near the Kazakhstan border. The proprietary camless pick-up allowed our fleet to operate through heavy morning dew without the clogging issues we faced with our previous German equipment. We increased our daily bale count by 20 percent while reducing our seasonal maintenance costs by nearly 40 percent because there are simply fewer bearings to fail.”

Case Study 2: Sugarcane Energy Provider in São Paulo, Brazil

“Sugarcane trash is notoriously abrasive and quickly wears down standard compression rollers. The EP-9YG-1.0, with its HRC 58-62 hardened gear steel rollers, has maintained its structural integrity for two full seasons with zero roller deformation. We reduced our machinery acquisition costs by 65 percent compared to Italian imports while achieving the high-density bales required for our biomass power plants.”

Case Study 3: Corn Stalk Specialist in Iowa, USA

“The hammer-claw conversion on the EP-9YG-1.0 is a game-changer for our livestock bedding operation. Being able to harvest standing corn stalks directly saves us an entire pass with the mower and rake, which has drastically reduced soil contamination in our bales. Under the US Farm Bill 2023 equipment incentives, this machine provided the best ROI for our 80-horsepower tractor fleet.”

Case Study 4: Alfalfa Cooperative in Saudi Arabia

“Operation in 45-degree desert heat requires a hydraulic system that does not leak under pressure. The H-type ferrule joints on our EVER-POWER balers have provided a 100 percent leak-free performance during our intensive pivot-irrigation harvest cycles. The internal buffer cylinders also protect the machine frame when we discharge bales at high speeds, extending the service life of our equipment significantly.”

Case Study 5: Smallholder Modernization Project in India

“Modernizing straw management is critical to reducing field burning in our region. The EP-9YG-1.0 was the perfect fit for our local 70-horsepower tractors, providing industrial-grade density in a package that is easy for our operators to maintain. The automatic net wrapping ensures that our wheat straw bales remain structurally sound during long-distance transport to bio-fuel processing centers.”

Frequently Asked Questions (FAQ)

Q: What is the minimum horsepower required?

A: A tractor with at least 48 kW (65 HP) is required for efficient baling and transport.

Q: How does the camless design reduce maintenance?

A: By removing the cam track and followers, the primary mechanical wear point is eliminated, preventing failures caused by dust and debris.

Q: Can I bale corn stalks directly with this unit?

A: Yes, by installing the specialized hammer-claw pick-up, you can collect standing stalks without prior mowing.

Q: What is the maximum bale density?

A: The EP-9YG-1.0 can achieve densities up to 200 kg per cubic meter, depending on material moisture.

Q: Are the rollers durable for rice straw?

A: Yes, all 16 rollers are induction-hardened to HRC 58-62 specifically to resist the abrasive silica in rice straw.

Q: Does it support automatic wrapping?

A: Yes, it features a sensor-triggered automatic net wrapping and cutting system.

Related Products for a Complete Harvest Workflow

To maximize the efficiency of your EP-9YG-1.0 Round Baler, we recommend the following integrated EVER-POWER solutions:

-

9GQY-3.2 Mower Conditioner: Designed for gramineous forage and reeds, featuring a double-suspension device and “hammer-type” conditioners to accelerate drying.

-

9LZY-9.0 Finger-Disk Rake (15 Discs): A high-capacity rake covering a 9-meter width with hydraulic lifting finger discs for uniform windrows and excellent air permeability.

-

9JYY-2.5 Bale Pickup and Transport Vehicle: A professional logistics solution capable of carrying up to 2500 kg with a hydraulic loading system to reduce soil compaction.

-

9F-70 Forage Crusher: For industrial biomass applications, this crusher processes finished bales into high-quality feedstock at a rate of 5 to 20 tons per hour.

Ready to Enhance Your Harvest Productivity?

Contact EVER-POWER Round Baler CO., LTD. today for a custom configuration and regional pricing analysis.

-

Global Headquarters: Modern Agricultural Machinery Industrial Park, Hulunbuir Economic Zone, Inner Mongolia.

-

International Sales: [email protected]

Reviews

There are no reviews yet.