Description

EP-9YG-2.24D (S9000) Round Baler: High-Density Forage Harvesting Powerhouse for Industrial-Scale Agriculture

The EVER-POWER 9YG-2.24D (S9000) is a premium heavy-duty round baler engineered for large-scale agricultural operations requiring high-density bales and maximum throughput. Utilizing a proprietary “axle-flow” semi-forced feeding mechanism and a revolutionary 90-degree rotating double-link gearbox, this machine eliminates traditional intake bottlenecks and maximizes maneuverability without cutting power.

Designed for tractors in the 55 to 100 kW range, it delivers industrial-grade bales of 500 to 1000 catty (250-500 kg), making it the preferred choice for professional straw logistics and biomass energy providers.

Five Key Facts

-

Massive Intake Capacity: A 2240mm ultra-wide pickup width, combined with a camless “axle-flow” mechanism, doubles feeding efficiency compared to traditional designs.

-

Extreme Maneuverability: The S9000 Beyond model features a double-link gearbox capable of 90-degree horizontal rotation, allowing for tight headland turns without interrupting PTO power delivery.

-

Industrial Compression Power: Equipped with 18 high-strength rollers driven by dual-side 20A reinforced chains to achieve consistent densities of 100 to 200 kg per cubic meter.

-

Advanced Hydraulic Reliability: The system utilizes H-type ferrule joints for higher pressure tolerance and integrated buffer cylinders to prevent structural fatigue during high-speed gate cycles.

-

Intelligent Automation: Sensor-controlled density monitoring and automatic net wrapping systems ensure every bale meets strict structural requirements for long-distance transport.

Modular Product Analysis (High-Value Technical Information)

Proprietary Axle-Flow Feeding and Camless Architecture

The 9YG-2.24D (S9000) utilizes a revolutionary camless pick-up design that addresses the primary failure points of traditional straw balers. By removing the high-maintenance cam tracks and bearings, EVER-POWER has created a feed path that is significantly quieter and resistant to debris buildup.

This “axle-flow” semi-forced feeding mechanism allows the machine to maintain a 100 percent increase in throughput over traditional tine-type systems. This is critical for processing abrasive rice straw or heavy wheat residues in high-dust environments where traditional cam bearings frequently seize.

The S9000 Beyond Double-Link Gearbox Advantage

Extreme maneuverability in smaller field plots is achieved through the specialized S9000 Beyond transverse traction frame. This model features a double-link gearbox that can rotate 90 degrees horizontally and adjust vertically to match uneven terrain.

Unlike standard balers that require the operator to disconnect the PTO during sharp turns to avoid drive shaft damage, the S9000 can operate continuously through 100-degree steering angles. This technology significantly reduces the turning radius and prevents mechanical “stuttering,” increasing overall daily productivity by up to 15 percent.

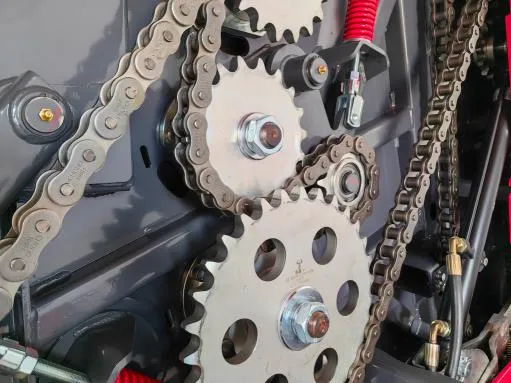

Structural Metallurgy and Roller Compression Chamber

Consistency in bale density is the foundation of industrial straw logistics, and the 9YG-2.24D achieves this through superior metallurgical standards. The compression chamber houses 18 precision-engineered rollers, each manufactured from high-grade gear steel and subjected to localized induction hardening.

With a surface hardness reaching HRC 58 to 62, these rollers resist wear from high-silica materials like rice straw. Driven by massive dual-side 20A chains, the rollers apply uniform pressure to create 500 to 1000 catty bales that are structurally stable for biomass energy processing.

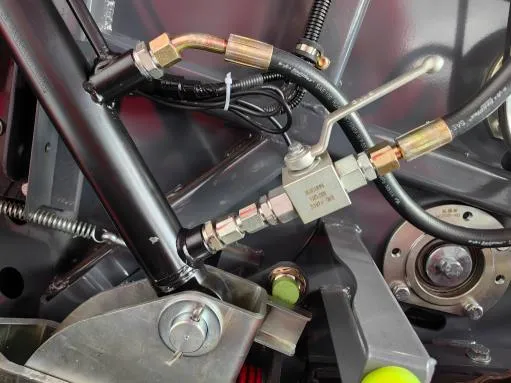

High-Pressure Hydraulic System and Buffer Protection

The EP-9YG-2.24D is fitted with an advanced hydraulic system that prioritizes speed and safety. By adopting H-type ferrule joints, the system handles higher pressure spikes, enabling faster gate opening and closing cycles without the risk of leaks.

Integrated buffer cylinders provide a critical safety layer by dampening the vibration and mechanical shock when the heavy rear gate closes. This engineering prevents structural cracking of the main frame and extends the service life of the machine during high-frequency industrial use.

Technical Specifications Table

| No. | Item | Unit | Specification |

| 1 | Model Name | / | EP-9YG 2.24D Round Baler (S9000) |

| 2 | Hitching Method | / | Trailed (Towed) |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure | / | Spring Tine Type |

| 5 | Feeder Structure | / | Tine Roller / Rotor Type |

| 6 | Bale Chamber Mechanism | / | Roller Type |

| 7 | Chamber Width | mm | 1400 |

| 8 | Chamber Diameter | mm | φ 1200 |

| 9 | Compression Elements | qty | 18 (Rollers) |

| 10 | Compression Roller Diameter | mm | φ 222 |

| 11 | Binding Method | / | Net Wrapping |

| 12 | Matched Power | kW | 55 – 100 |

| 13 | Structural Mass (Weight) | kg | 4262 |

| 14 | PTO Speed | r/min | 720 |

| 15 | Overall Dimensions (L × W × H) | mm | 4240 × 3010 × 2450 (Working State) |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Size (Diameter × Width) | mm | φ 1300 × 1400 |

| 18 | Bale Density | kg/m³ | 100 – 200 |

| 19 | Productivity | Bales/h | 40 – 100 |

| 20 | Wheel Track | mm | 2600 |

| 21 | Operating Speed | km/h | 5 – 35 |

| 22 | Net Wrap Specifications | m | 2000 × 1.4 |

| Feature | S9000 Pro Specification | S9000 Classic Specification |

| Pick-up Width | 2240 mm | 2240 mm |

| Bale Size | Φ1300 x 1400 mm | Φ1300 x 1400 mm |

| Required Power | 55 to 100 kW | 55 to 100 kW |

| Compression Chamber | 18 Rollers (Φ222 mm) | 18 Rollers (Φ222 mm) |

| Gearbox Design | 90-Degree Rotating Double-Link | Dual Universal Safety Torque |

| Binding System | Automatic Net Wrapping | Automatic Net Wrapping |

| Hydraulic Type | H-type Ferrule with Buffer | H-type Ferrule with Buffer |

| Chain Specification | Dual-Side 20A Reinforced | Dual-Side 20A Reinforced |

| Structure Weight | 4570 kg | 4312 kg |

| Productivity | 40 to 100 bales per hour | 40 to 100 bales per hour |

| Density Range | 100 to 200 kg/m³ | 100 to 200 kg/m³ |

Global Application Scenarios

The 9YG-2.24D (S9000) is optimized for 80 distinct agricultural and industrial workflows, including:

-

US Midwest Corn Belt: Processing massive amounts of dry corn stalks into high-density fuel feedstock.

-

Brazilian Sugarcane Hubs: Collecting abrasive sugarcane residue post-harvest for industrial biomass power.

-

Australian Wheat Belt: Handling ultra-wide header windrows with the 2240mm pick-up.

-

Russian Steppes: Large-scale silage production in short, 24-hour harvest windows.

-

Saudi Pivot-Irrigated Alfalfa: Precision baling of high-value forage in desert conditions.

-

Inner Mongolian Steppe: Harvesting massive areas of wild pasture grass for winter survival stockpiles.

-

Canadian Prairie Flax: Managing the tough, wiry fibers of flax straw without machine wrapping.

-

Southeast Asian Rice Paddies: Efficient collection of abrasive rice straw for paper pulp production.

Brand Compatibility and Replacement Guide

The 9YG-2.24D (S9000) is precision-engineered to replace premium equipment from the world’s top brands, offering superior technology at a significantly lower capital investment.

| Target Brand | Comparable Model | EVER-POWER S9000 Replacement Advantage |

| John Deere | 560M / 569 Series | 35% lower cost; 90-degree rotating gearbox eliminates drive shaft stutter. |

| Krone | Comprima V150 XC | Camless pick-up reduces maintenance downtime in abrasive rice straw. |

| New Holland | Roll-Belt 560 | H-type ferrule hydraulic joints provide higher reliability under industrial cycles. |

| Claas | Variant 480 | More robust frame design specifically for harsh terrains in Russia and Brazil. |

| Vermeer | 605N / 605M | Proprietary axle-flow feeding doubles throughput in high-volume silage. |

| Kuhn | VB 3190 | Reinforced 20A dual-side chains handle higher torque loads in standing corn stalks. |

| Massey Ferguson | RB Series | Induction-hardened rollers (HRC 58-62) offer superior wear resistance in silica-rich straw. |

Installation and Maintenance Guide

Step 1: Mechanical Hitching and Transverse Alignment

Align the tractor hitch with the S9000 Beyond transverse traction frame. The frame’s vertical flexibility allows for easy pin insertion through the tractor’s suspension arms even on uneven ground. Secure the heavy-duty locking pin and verify the 90-degree horizontal rotation capability.

Step 2: PTO and Safety Torque Integration

Connect the safety torque drive shaft to the tractor’s PTO output (standard 720 r/min).5 Ensure the dual-universal joints are correctly phased to prevent mechanical “stuttering” during sharp turns. This design allows for continuous operation during row-end maneuvers.

Step 3: Hydraulic Calibration (H-Type Joints)

Attach the hydraulic hoses using the S9000’s high-pressure H-type ferrule joints. Perform a test cycle of the rear gate to verify the buffer cylinder performance. The cylinders should dampen the gate’s closing force, protecting the main frame from shock-induced stress.

Step 4: Electronic Density and Monitor Setup

Mount the control monitor in the tractor cabin and connect the electronic density sensors. These sensors provide real-time feedback on the bale formation inside the 18-roller chamber. Adjust ground speed (5-20 km/h) based on the monitor’s density targets to ensure uniform bale quality.

Step 5: Net Wrapping Dispenser Loading

Load a standard 1.4m wide net roll into the front dispenser. Thread the net through the automatic tensioners and calibrate the trigger point for density-based wrapping. Once initialized, the system will automatically wrap and eject finished 500-1000 catty bales.

Customer Success Stories

-

Large-Scale Cereal Contractor in Russia (Orenburg): “The 90-degree rotating gearbox has been the most significant improvement; our operators can now make sharp turns at the end of every row without disconnecting the PTO. This has increased our daily productivity by nearly 20 percent.”

-

Biomass Energy Provider in Brazil (São Paulo): “Managing abrasive sugarcane residues used to be a maintenance nightmare. The induction-hardened rollers of the 9YG-2.24D have provided the wear resistance we need, reducing our machinery investment costs by 65 percent compared to German imports.”

-

Standing Corn Stalk Harvesting in Northern China: “The specialized feeding mechanism of the 9YG-2.24D allows us to harvest standing corn stalks directly, saving us the entire cost of mowing and raking.”

Frequently Asked Questions (FAQ)

- What is the minimum tractor power required?

A tractor with at least 55 kW (75 HP) is required for effective baling and transport.

- How does the S9000 Beyond gearbox improve efficiency?

It allows for 90-degree horizontal rotation without disconnecting the PTO, reducing turn time by 15 percent.

- What is the maximum bale density?

The 9YG-2.24D can achieve densities up to 200 kg per cubic meter.

- How does the camless design reduce maintenance?

By removing the cam track and bearings, the primary point of mechanical failure and operational noise is eliminated.

- Is the hydraulic system compatible with all tractors?

Yes, it uses standard connections with upgraded H-type ferrule joints for high-pressure durability.

- Can I bale corn stalks directly?

Yes, the “axle-flow” mechanism is designed to handle heavy residues like corn stalks and abrasive rice straw.

- What is the width of the pick-up?

The machine features a massive 2240mm pick-up width for high-volume intake.

Related Products for a Professional Harvest Workflow

To maximize the efficiency of your 9YG-2.24D (S9000) Round Baler, we recommend the following integrated solutions:

-

9GQY-3.2 Mower Conditioner: Specifically designed for gramineous pasture and reeds, this mower conditioner uses a double-suspension system to ensure a clean cut across uneven ground.

-

9LZY-9.0 Finger-Disk Rake (15 Discs): This ultra-wide rake covers 9 meters in a single pass, aggregating forage into uniform, airy windrows that match the 2240mm intake of the 9YG-2.24D.

-

9JYY-4.5 Bale Pickup and Transport Vehicle: Capable of loading up to 4500 kg using tractor hydraulics, it eliminates the need for manual handling and minimizes soil compaction.

-

4BYH-2.6 Kidney Bean Puller: For specialized legume harvesting, the 4BYH-2.6 aggregates bean residues into clean rows, ensuring your S9000 baler collects clean, low-soil material.

Ready to Maximize Your Harvest Productivity?

Contact EVER-POWER Round Baler CO., LTD. today for a custom configuration and regional pricing analysis.

Global Headquarters: Modern Agricultural Machinery Industrial Park, Hulunbuir Economic Zone, Inner Mongolia.

International Sales: [email protected]

Reviews

There are no reviews yet.